Food Grade Conveyor Belt Cleaning System

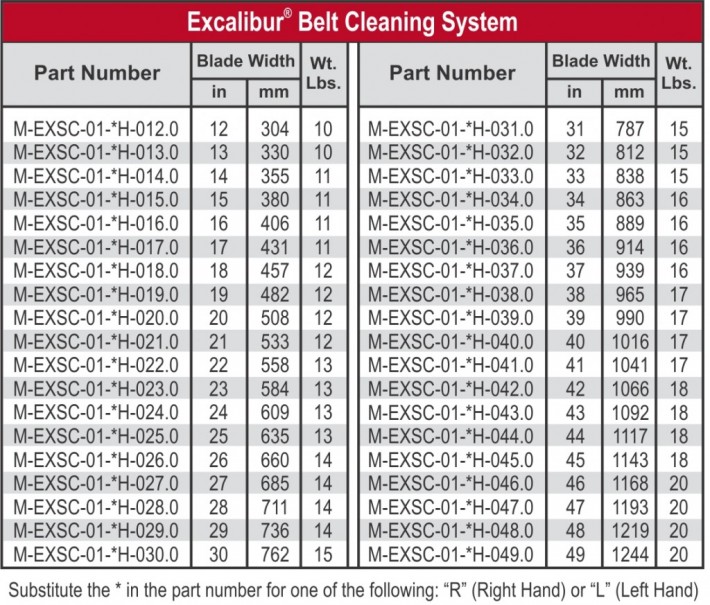

Uses a unique blade, holder and tensioning mechanism. Excalibur® is particularly suited for light duty thermoplastic belts with widths from 300mm – 1244mm.

Excalibur® is designed and configured to meet the most stringent sanitary requirements of the food manufacturing industry and uses USFDA, USDA and BISSC approved materials. In fact, no other belt cleaner offers these crucial operational features, saving customers money while assuring safe, high quality manufacturing.

Food Grade Belt Cleaner Features & Benefits

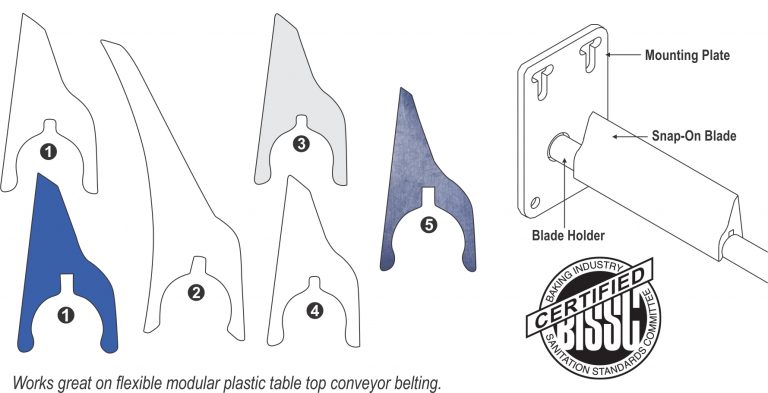

- Works great on flexible modular plastic table top conveyor belting

- Sanitary and safe lightweight

- Features a unique blade, holder and tensioning mechanism

- Snap-on/off conveyor belt scraper blade

- Many belt cleaning blade materials available

- Complete disassembly in seconds

- Precision tension selection with torsion spring tensioner

- 300 Series Electro-polished stainless steel

- BISSC certified design

- FDA/USDA compliant materials

- Primary and secondary conveyor belt cleaner mounting location

Excalibur Video

Excalibur Blades & Parts

- UHMW & UMHW Blue

- Long Neck UHMW

- FDA Oil Impregnated

- Nylon Blade

- Metal Detection

The Importance of Using Food Grade Conveyor Belt Cleaners in Food Processing Industry

Introduction

In the food processing industry, hygiene and safety are paramount. The use of food grade conveyor belt cleaners plays a crucial role in maintaining these standards. These specialised cleaners are designed to meet the strict hygiene requirements of the food industry, ensuring that the conveyor belts used in food processing are free from contaminants and safe for food contact.

1. Ensuring Food Safety

The primary importance of using food grade conveyor belt cleaners lies in their ability to ensure food safety. Food contamination can occur at any stage of processing, and conveyor belts are no exception. These cleaners are designed to effectively remove food particles, bacteria, and other contaminants from the conveyor belt, thereby reducing the risk of foodborne illnesses and ensuring that the food remains safe for consumption.

2. Compliance with Health Regulations

Food processing facilities are subject to stringent health and safety regulations. Using food grade conveyor belt cleaners helps these facilities comply with these regulations. These cleaners are typically made from materials that are approved for direct food contact and do not introduce any harmful substances into the food products.

3. Extending Shelf Life of Food Products

By maintaining a high level of cleanliness on conveyor belts, food grade conveyor belt cleaners can help in extending the shelf life of food products. A cleaner processing environment reduces the risk of early spoilage and decay, ensuring that the food products remain fresh for longer periods.

4. Enhancing Product Quality

Clean conveyor belts mean no cross-contamination of flavours, odours, or colours, which is critical in maintaining the quality of food products. Food grade conveyor belt cleaners ensure that each product maintains its intended quality, taste, and appearance, which is crucial for consumer satisfaction and brand reputation.

5. Reducing Maintenance and Downtime

Clean conveyor belts are less likely to experience malfunctions due to the build-up of residues. By using food grade conveyor belt cleaners, food processing facilities can reduce the frequency of maintenance and minimize downtime, leading to increased efficiency and productivity.

6. Environmental Considerations

Food grade conveyor belt cleaners are often designed to be environmentally friendly, using less water and chemicals than traditional cleaning methods. This not only helps in reducing the environmental footprint of the food processing facility but also ensures that the waste water is less likely to contain harmful contaminants.

Conclusion

The use of food grade conveyor belt cleaners is essential in the food processing industry. They play a vital role in ensuring food safety, compliance with health regulations, and maintaining the quality of food products. Additionally, these cleaners contribute to operational efficiency and environmental sustainability. Investing in high-quality food grade conveyor belt cleaners is a crucial step for any food processing facility committed to maintaining the highest standards of hygiene and safety.

References:

- Food Safety Standards and Regulations

- Innovations in Conveyor Belt Cleaning Technology

- Environmental Best Practices in Food Processing

In summary, food grade belt cleaners are an integral part of the food processing industry, ensuring the safety, quality, and efficiency of food production processes.