FMS belt scales are used for weighing every kind of heavy, bulky goods. The main areas of application are found in gravel works, quarries, mining and tunnelling or the recycling of building waste and excavated material. The main components of a belt scale are the measuring roller and the associated electronics.The electronic system evaluates and displays the most important parameters. The focus of development is on simple operation, a stable construction and the universal possibilities for control connections via Ethernet interfaces. FMS belt scales are second to none in terms of robust construction and reliable function.

Your Advangages

Properties

- Heavy aluminium housing with resistant display and controls

- Graphical display, auto tare function, calibration via integrated calculation

- Integrated web browser

- Integrated Profinet IRT interface

Our Promise

- Easy installation

- High reliability and long service life

- Maintenance-free operation

FMS Belt Scales

Our Offer To You

- Reduce downtime due to unscheduled break downs

- Save on equipment cost & renewal costs

- Save man hours on maintenance

- Minimising & eliminating lost production

- Increase their bottom line by achieving savings in all of the above

A weight off your mind.

When continuity of operations really matters, you need a belt scale you can rely on. So it’s time you discovered one of the best-kept secrets in the bulk materials industry.

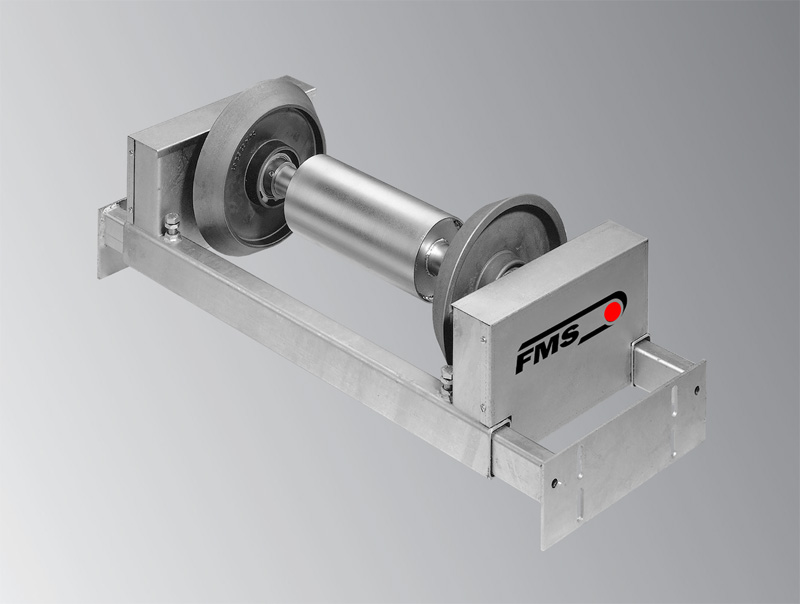

If you were asked to name leading providers of technology for handling bulk materials, you probably wouldn’t come up with FMS. Yet over the past 25 years, this Swiss engineering firm has quietly established its belt scale as the most robust and accurate solution around for measuring material flow. The company’s BMGZ belt scales are used in conveyer belts in settings across Europe, including quarries, gravel works, construction sites, loading stations and tunnel drilling operations.

Unique design

The design of the FMS belt scale is unique. Unlike in rival belt scales, the speed sensor is housed inside the measuring roller and there are no exposed cables. This greatly reduces the risk of damage from debris and the local climate. In turn, this helps maintain uninterrupted conveyer belt operation – something that’s critical in bulk materials industries. This design provides unparalleled accuracy. Scales that do not have the BMGZ’s integrated speed sensor typically use a friction wheel which is exposed to the elements. This in turn makes is susceptible to contamination and relies on a sprung loaded lever for contact with the conveyor. The resulting possible slippage makes the speed measurements, and consequently the calculated flow rate, less reliable.

Despite these advantages, Zürich-based FMS Force Measuring Systems remains much better known for its engineering excellence in other markets. It is a world leader in web tension measurement and web guiding solutions for the converting industries that make materials such as foil, paper, textiles, cable, wire, rope and cloth. The best-in-class force-measuring bearings it uses in these solutions are also at the heart of the BMGZ scales.

Failure-free operation

One company that has discovered FMS belt scales in recent years is Holcim Schweiz AG, a subsidiary of Holcim Ltd. Nine BMGZ scales are in use at its Hüntwangen gravel plant in Switzerland. Walter Rutschmann, the site’s head of maintenance, says: “When it came to purchasing new conveyor belt scales, we looked around the market. We decided on the solutions from FMS.

“The BMGZ series has turned out to be particularly robust and reliable against disturbing factors. Since initial start-up, we have not experienced any failures at all.

“It ensures maintenance-free operation, which is particularly important to me in saving resources and costs.”

Spreading the word

Based on successes like these, FMS is on a mission to bring its belt scales to more markets around Europe. Spearheading this move in the UK is business development manager Sertan Osman. “Many of our belt scales have been in continuous use for more than 20 years,” he says. “They’ve proved to be incredibly durable. As a result, we’ve got a core of loyal, very satisfied customers in the bulk materials industries. This tells us we’ve got a solution more companies need to hear about.”

The BMGZ series is available in a range of roller widths and its galvanised mounting frame features slotted end plates for fine-tuning of position as well as extendable steel legs. This means it is compatible with all conveyer types and sizes in stationary as well as mobile applications. Meanwhile, Ethernet connectivity allows operators to configure and manage the scales from any connected computer. The scales are installed and maintained by top-notch engineers from FMS’s network of service partners.

Save Time & Money with Hoverdale

- Total transparency – get the best advice from the people who are directly involved in engineering and installing the solutions

- Improving housekeeping – working with you to reduce spillage and to determine the benefits in terms of reduced maintenance & clean-up costs

- Increasing plant availability – extending the periods between maintenance by installing the right solution

- We work with you to achieve a program of planned maintenance – we can custom-make products to last the length of time you need them to last to fit in with your planned maintenance programme

- Engineering solutions to high-cost maintenance problems – our engineering expertise gives us a unique ability to dramatically reduce maintenance costs with the most simple solutions

- Reducing maintenance costs – the correctly designed conveyor system will have a huge effect on maintenance costs that we can help you to identify, quantify and realise