Plough Grinding

Hoverdale are UK leaders in Plough Grinding. We are the only company in the UK that can undertake stainless steel grinding & aluminium grinding.

What is Plough Grinding?

Plough Grinding is the removal of material by a grinding process using a ‘plough’ grinding machine. Lumsden is the name of a make of machine and it has become synonymous with the process much as Hoover is to vacuum cleaners.

Advantages of Plough Grinding

The advantage of this method of machining over other methods is much higher rates of material removal compared to ‘surface grinding’. Generally, larger areas can be machined without leaving ‘witness’ lines than with conventional machining (milling).

Our machines are capable of high performance and metal removal rates of up to 312 cu cm/hour. This competes with other forms of machining and has a better finish

What Makes Us Different?

- We have capacity in depth with large machines up to 120 inches in diameter

- We are the only company that can grind stainless steel as a viable commercial process

- We are the only company that can grind aluminium as a viable commercial process

Our Grinding Capacity

- 4 grinding machines

- The largest capacity of our machines is 4m x 1.8m x 1.25m under wheel head

- In imperial measurements, our machines have a diameter of up to 120 inches

- The tolerances of our machines is 0.2mm (8 thou) +/-0.1 (4 thou)

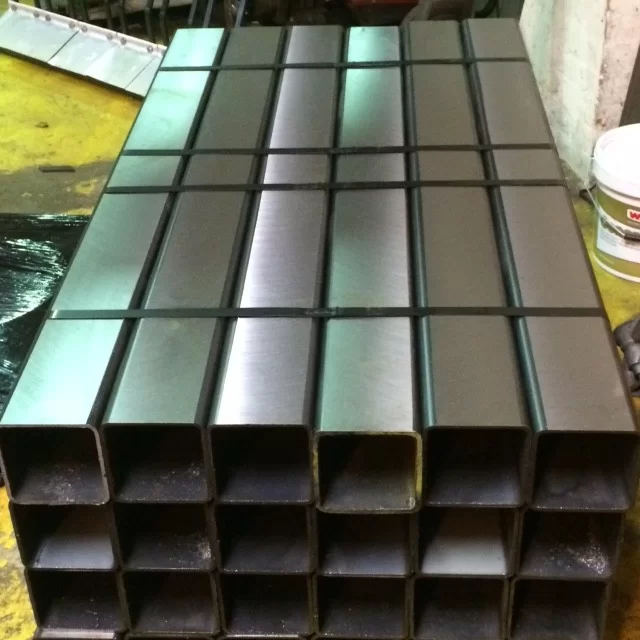

Stainless Steel Grinding

The traditional method of holding work to be grounds is on a magnetic chuck, as Stainless Steel is non-magnetic we have developed a method of work holding which overcomes this. We have over 30 years’ experience of doing this

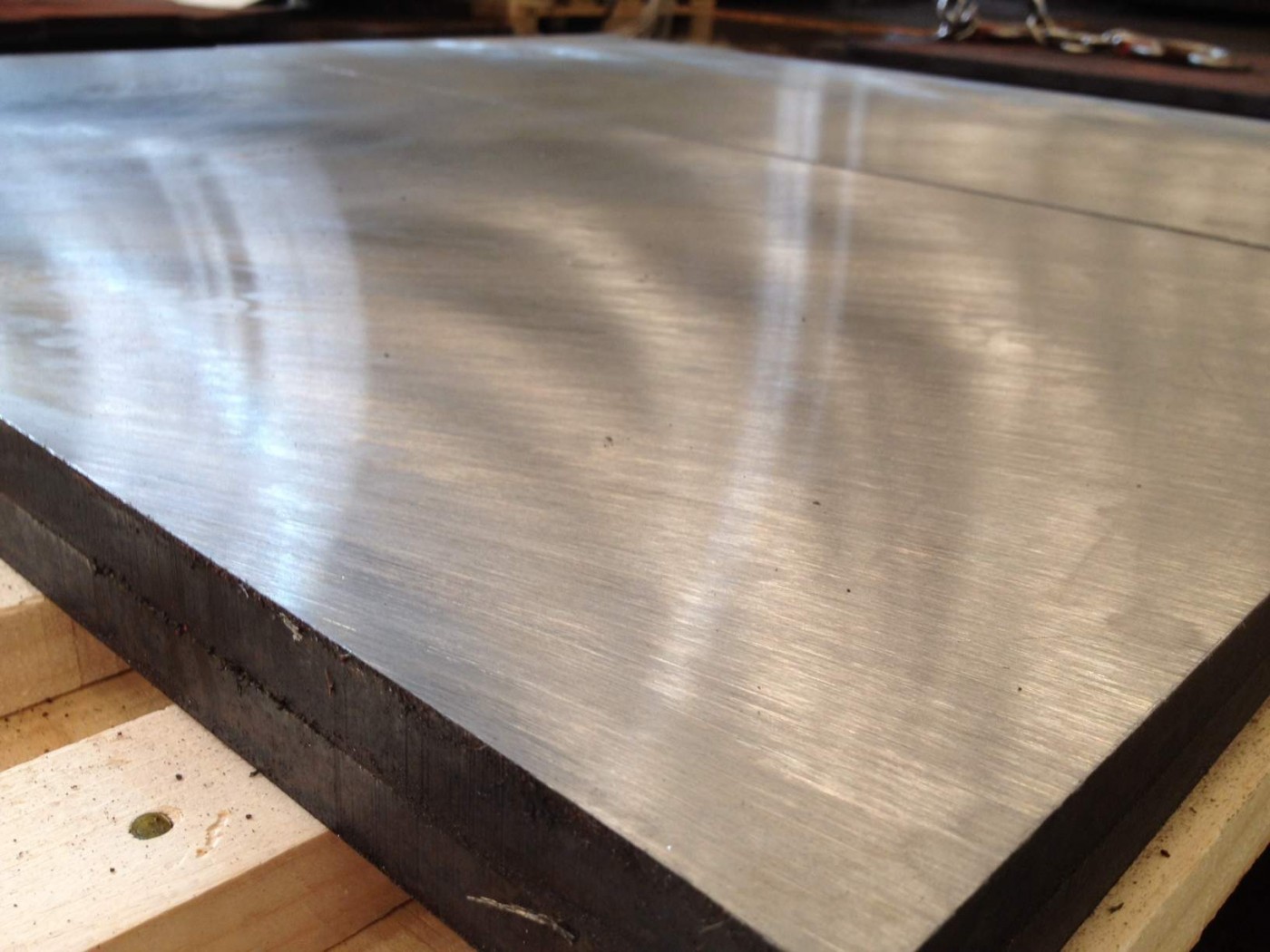

Aluminium Grinding

The traditional method of holding work to be grounds is on a magnetic chuck, as Aluminium is non-magnetic we have developed a method of work holding which overcomes this. We have over 30 years’ experience of doing this

What machines do you have? Why are these the right & the best machines for the job?

We have a 1200mm rotary machine, this will grind any profile that will fit inside a 1200mm diameter circle, we also have a reciprocating machine that will grind any profile that will fit inside a rectangular area 2000mm x 600mm

Frequently Asked Questions

Turnaround – How quickly can you turnaround the work?

Most Jobs can be completed within 5 working days. Work can be completed on the same day as it is delivered if prior notice is given.

How is this favourable to milling or other means of grinding metal?

We can achieve metal removal times akin to Milling with a surface finish of Ra 2.5 (equal to finish machining). The cost of this is far lower than using these other methods

Tolerances – what are the tolerances of your machines?

The general tolerance that we offer on thickness is +/- 0.2mm

Experience – what experience do you & the company have? How experienced are your grinders? Why does this make a difference?

Our key operators have been working for us doing this process for 25+ years. We specialise in the grinding of stainless steel plate which is then used in the petrochemical, architectural & marine industries.

What other work can you do?

We can supply Ground Blanks in Mild Steel and Stainless Steel. We specialise in Aluminium grinding eg blocks for injection moulding machines.

We can clean up both faces of a blank or alternatively just one. All machines are capable of grinding multiple components with advantages over other methods of machining ideal for jog bases and tool blocks which can be pre-ground to go straight on to a CNC machine.

Our machine grinding capabilities include surface grinding, cylindrical grinding, centerless grinding, and more. We utilize advanced machinery and cutting-edge technologies to ensure the highest quality and accuracy in every project.

Can We Help?

We would like to offer you a free site survey with a report and recommendations. We offer a pro rata payment plan where if you accept our recommendation you only pay the full price when we achieve our promised results.

We can work with you to achieve the planned maintenance program by making components last longer by the strategic use of hard metals/ceramics.