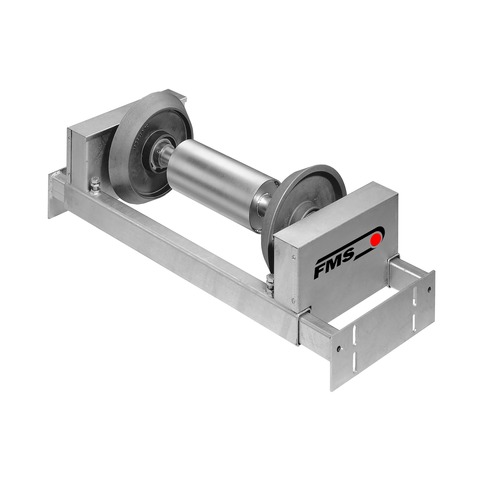

BMGZ041 – Robust Measuring Rollers for troughed conveyor belts

- Longest lifetime

Robust design, all components enclosed, integrated, contact-less speed detection - Precise measuring results

10‘000-times proven technology, direct force detection on the shaft, w/o deflection or any braces - Compact, maintenance-free

Integrated speed detection without friction wheel, dual shaft sealings - Simple and universal retrofit

Sophisticated and proven concept with multiple installation options

BMGZ041-Series

The toughed measuring rollers of the BMGZ041 series are designed for operation in most severe conditions and under steady load in mobile and stationary plants that process heavy, bulky goods, such as sand, gravel, stones, coal, building rubble etc. A wide portfolio of sizes and troughing angles for standard belts offers solutions for most applications. The beveled side disks are slidable and allow for easy adjustment to non-standard belt types and dimensions.

Functional description

The FMS measuring roller normally substitutes a regular idler roller station of the conveyor belt. The FMS measuring roller is selected according to the width and troughing angle of the conveyor belt. The center roller and the two beveled side disks are mechanically separated and allow for easy adjustment of the belt cross section according to your specific belt type or dimensions. Both measuring roller axis are supported by force measuring sensors. This direct measurement at the point of load transmission makes the measuring system insensitive to forces that act in direction of the moving belt. Additional components (guiding beams and connections to the frame, etc.) to isolate the force are not required and lead to an extremely slim design. With an installation height of only 180 mm (7.1 in.) or 240 mm (9.5 in.) the FMS measuring roller can be easily installed where space is limited, e.g. in mobile crushers or screening plants. The adjustable support of the measuring roller can be adapted to various frame dimensions and widths.