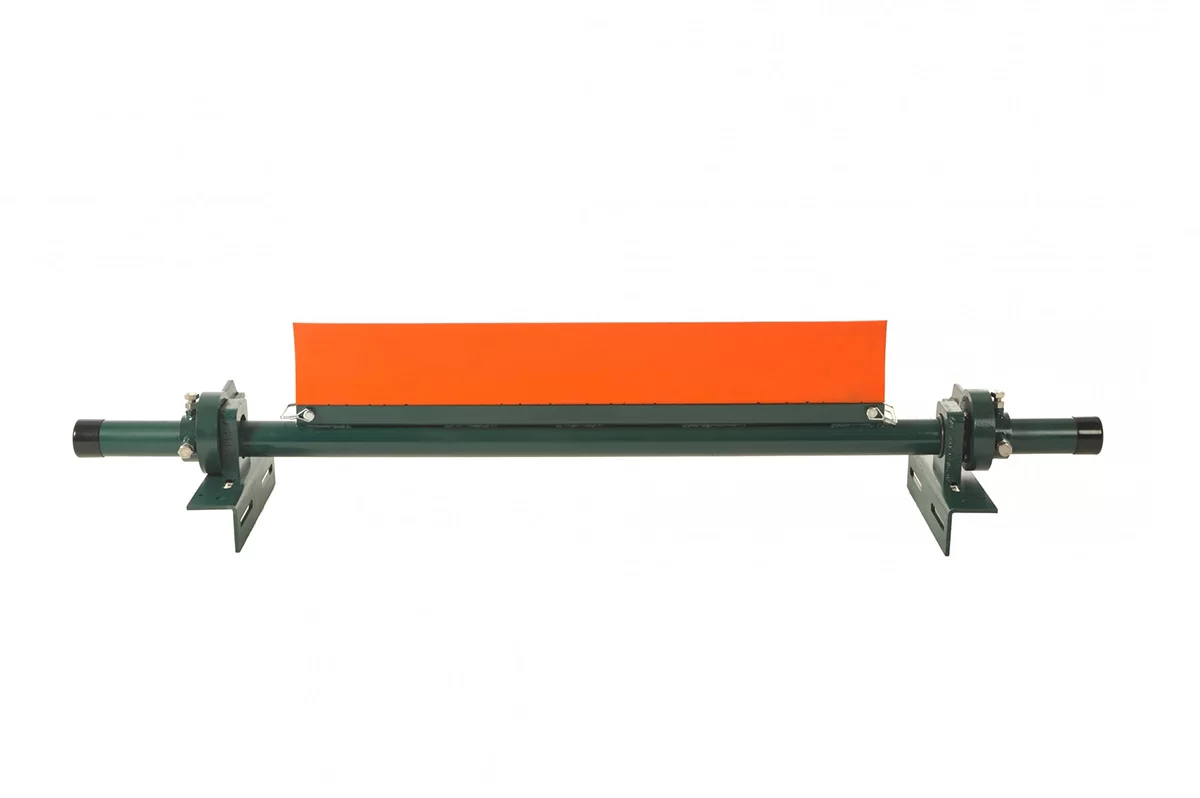

RC Polyurethane Primary Belt Cleaner

RC Polyurethane Primary Belt Cleaner

Clog-free & Low Maintenance

A heavy-duty primary cleaner that is belt-friendly and will run with metal fasteners.

The rapid change blade system makes changing the blade quick and easy (the record is 8 seconds to change).

Heavy-duty torsion blocks are available and provide constant pressure on the blades, which react individually to any unevenness on the belt surface.

T-Type Primary Belt Cleaner Features & Benefits

- Multi-blades with individual suspension – no material missed & easier to maintain

- 4 blade options (polyurethane, tungsten carbide, boron carbide & industrial diamond impregnated blades)- ensuring the right blade for the right application to maximise the life of the blade

- Up to 2 years blade life – reduce replacement costs by up to 80%

- Operates in either direction – ideal for reversing belts

- Easily accessible to monitor and inspect – minimises downtime & maximising operational efficiency

- Long periods between maintenance – minimising maintenance costs & reducing man hours

- Returns carryback material to main flow – minimises spillages & clean-up time

- Self-adjusting with 3 options – Torsion tube, Air module, Torsion bush.

The Essential Role of Primary Belt Cleaners in Conveyor System Efficiency

Introduction

In the world of material handling, conveyor systems play a crucial role in transporting a wide range of materials in industries such as recycling, mining, agriculture, manufacturing, and construction. The efficiency and reliability of these systems are paramount, and one often overlooked component that plays a significant role in maintaining these systems is the primary belt cleaner.

The Halo Hoverdale Automated Linked Technology represents the pinnacle of conveyor belt cleaning innovation, providing a fully automated and interconnected solution for material handling challenges.

Can We Help?

We would like to offer you a free site survey with a report and recommendations. We offer a pro rata payment plan where if you accept our recommendation you only pay the full price when we achieve our promised results.

We can work with you to achieve the planned maintenance program by making components last longer by the strategic use of hard metals/ceramics.