Conveyor belt skirting is normally used at transfer points to prevent spillage. There are a wide range of different systems available – not all of them good.

We have three basic systems:

- Ultraclad 800 for coke or belts carrying a thick bed of material.

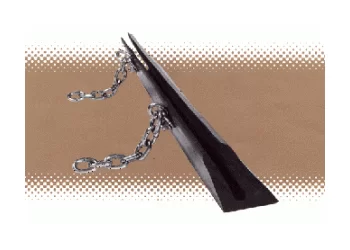

- A self-adjusting ‘floating’ seal that sits on the belt under its own weight.

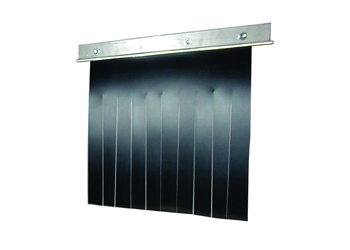

- K Skirt – a rubber seal with a double sealing arrangement to give improved performance and long life.

Hoverdale has a unique combination of experience and engineering know-how that we can guarantee you won’t find anywhere else. We can solve problems where others have failed. We have distinguishing factors that we hope will be relevant to you, including:

- All of our systems are designed to move with the belt and are self-adjusting – all other systems need adjustment and maintenance.

- We manufacture all of our conveyor belt skirting in the UK, offering our own range of products to do the job perfectly each time.

- We offer a free survey and report to assess the situation and make recommendations.

- We offer a free trial of one to four recommendations.

- We stand behind our products 100% – if any of our products don’t give the service they should, we will sort it out.

- We tailor our solutions to meet your needs.

- We offer total transparency – you get the best advice from the people who are directly involved in engineering and installing the solutions.

All of our conveyor belts and conveyor equipment is Made in Britain.

Our self-adjusting systems ‘ride’ with the belt and need no adjustment, only replacement when they are worn out. These systems generally give significant savings on maintenance & clearing-up. A typical example might be:

Before

- Normal clear-up twice a week (8 hours with truck) £500 per week

- Fitter to adjust & replace £240 per week

- Annual cost: £38,480

After (Assuming a typical order of skirt seal & installation: £2,000)

- Clear-up – 2 hours per month £130 per month

- Fitter to adjust & replace £480 per 8 months

- Annual cost £2,280

We have 3 systems that can help to reduce spillage at transfer points. Each of them can do the job & there will be one that will be able to deliver the right solution to your problem at the right cost. Give us a call & we’ll be happy to advise.

There are a number of ways of doing this: By using the correct skirting, you can reduce maintenance & clean-up costs. We can also advise as to how to strategically reinforce your plant using our hard metal expertise so as to give you the most long-lasting system at the most cost-effective rate. Finally, our conveyor cleaners & trackers can ensure that your materials discharge where they are supposed to so that you minimise friction, belt damage & structural damage.

Yes. Our K skirt & Atlastaseal products move with the belt to ensure the most effective seal and to maximise belt life.

Our Offer To You

- Reduce downtime due to unscheduled break downs

- Save on equipment cost & renewal costs

- Save man hours on maintenance

- Minimising & eliminating lost production

- Increase their bottom line by achieving savings in all of the above

Save Time & Money with Hoverdale

- Total transparency – get the best advice from the people who are directly involved in engineering and installing the solutions

- Improving housekeeping – working with you to reduce spillage and to determine the benefits in terms of reduced maintenance & clean-up costs

- Increasing plant availability – extending the periods between maintenance by installing the right solution

- We work with you to achieve a program of planned maintenance – we can custom-make products to last the length of time you need them to last to fit in with your planned maintenance programme

- Engineering solutions to high-cost maintenance problems – our engineering expertise gives us a unique ability to dramatically reduce maintenance costs with the most simple solutions

- Reducing maintenance costs – the correctly designed conveyor system will have a huge effect on maintenance costs that we can help you to identify, quantify and realise